|

Resource usageIn order to better promote energy management, the company has formulated a practical management system, and led and promoted the specific implementation of energy conservation and emission reduction work through a top-down organizational structure, such as the "Energy Conservation Technology Development Committee" in the factories in China and Vietnam.

In 2020, the China plant set an energy saving target of 10 plants including Kunshan, Shenzhen and Huai’an to achieve a 4.23% reduction in electricity consumption compared to last year, and a 6.25% decrease in carbon emissions per unit output value compared with last year; Vietnam plant set a power saving target to reduce electricity consumption compared with 2019 3.00%. As of the end of the reporting period, the production parks in China achieved electricity savings of 24,746.35 kilowatt-hours, and the production parks in Vietnam achieved electricity savings of 539.69 kilowatt-hours. |

class=title esgList

節能立項專案實例昆山廠區將傳統焊接機改善為節能型焊接機 |

class=title weldinglist

傳統焊接機 - 電壓功率為380伏,含冷水機2.80千瓦,綜合14.80千瓦。

- 散熱影響周邊環境溫度40 ~50攝氏度,占地面積4.70平方米

- 占地空間大且耗能功率較大

節能型焊接機 - 電壓降至220伏,設備功率1.76千瓦。

- 散熱對周邊環境溫度低至25~30攝氏度,占地面積縮減為1.60平方米。

- 焊接機實行結構一體化,達到了減少能耗、損失的目的。

|

class=title weldinglist

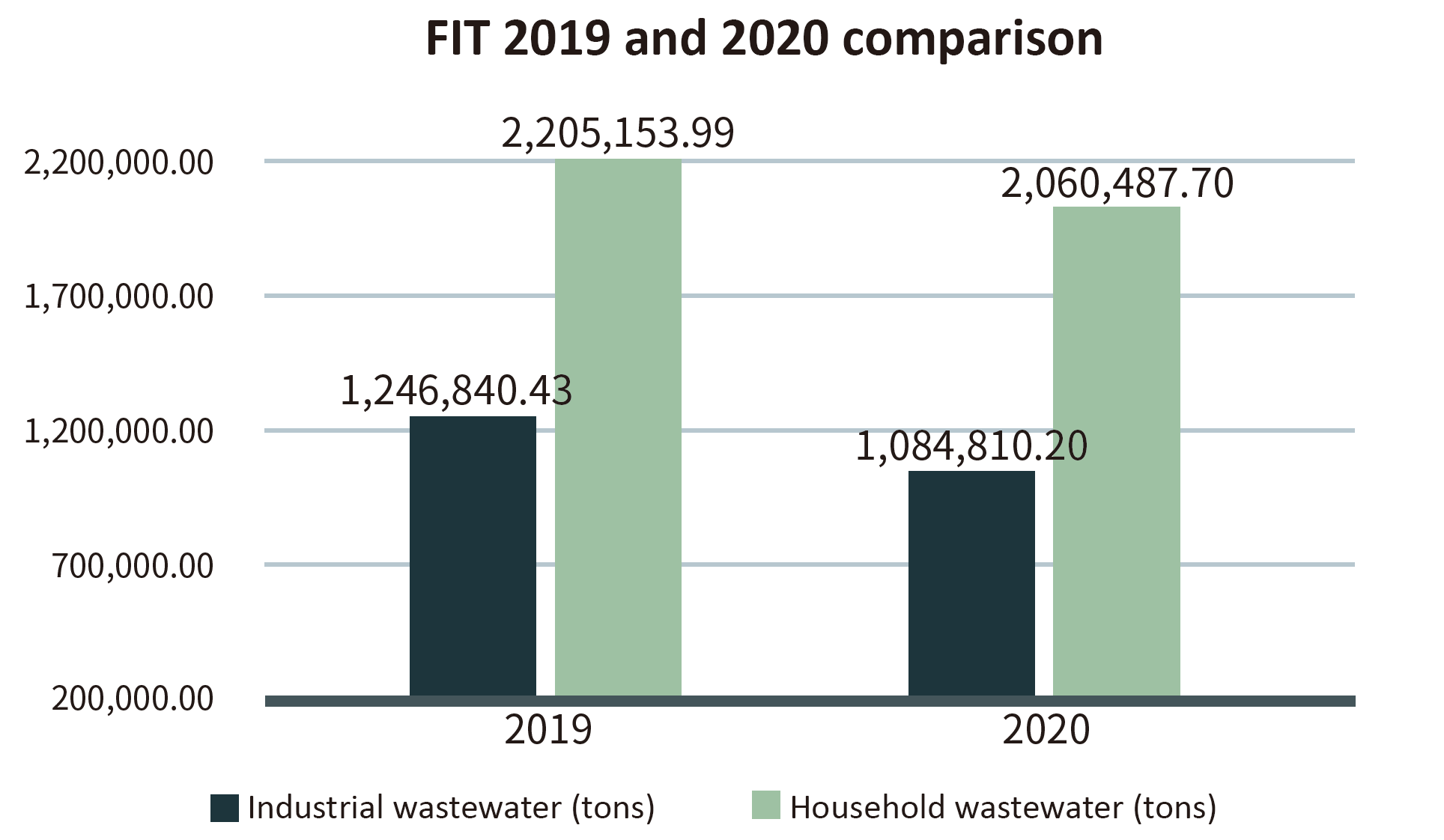

Water resource managementIn 2020, the total annual water consumption of FIT is 5,735,143.99 tons, a year-on-year increase of 1.65% compared with the total water consumption in 2019 (see the annual comparison chart below for the comparison of water consumption). |

class=title greenList

Wastewater is managed through Waste Water Management and Control Operating System. FIT has set up wastewater recycling operations in each production area.

Industrial wastewater is mostly generated from production and support processes such as manufacturing processes, surface treatment and water purification, while household wastewater is mostly generated from living facilities such as dormitories, commercial areas, restaurants, and toilets. |  |

|

tabA class=title addgreencheck

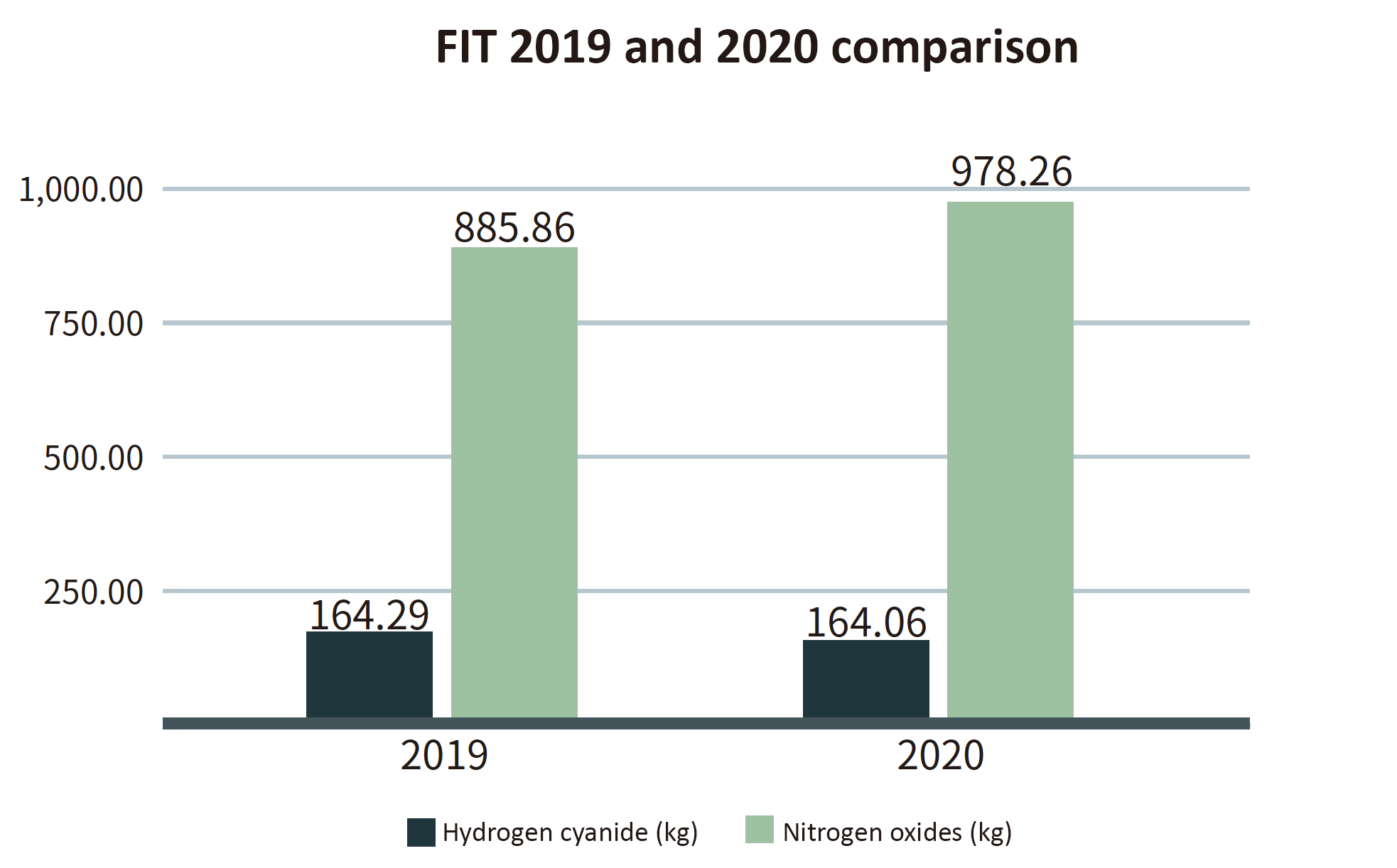

FIT emphasizes source control. The production process and equipment are all closed, and open operations are avoided as much as possible to reduce unorganized emissions. After the exhaust gas is discharged, the company will take corresponding supervision and control measures, including exhaust gas measurement. The company conducts regular outsourced monitoring every year, and improves the emission equipment and waste gas management process with reference to the effective measurement results to ensure that the waste gas emissions can continue to meet the requirements of environmental protection regulations. Take the emissions of hydrogen cyanide and nitrogen oxides as an example (see the comparison chart in the right column for the comparison of hydrogen cyanide and gaseous compounds by year comparison chart). |  |

|

tabB class=title addgreencheck

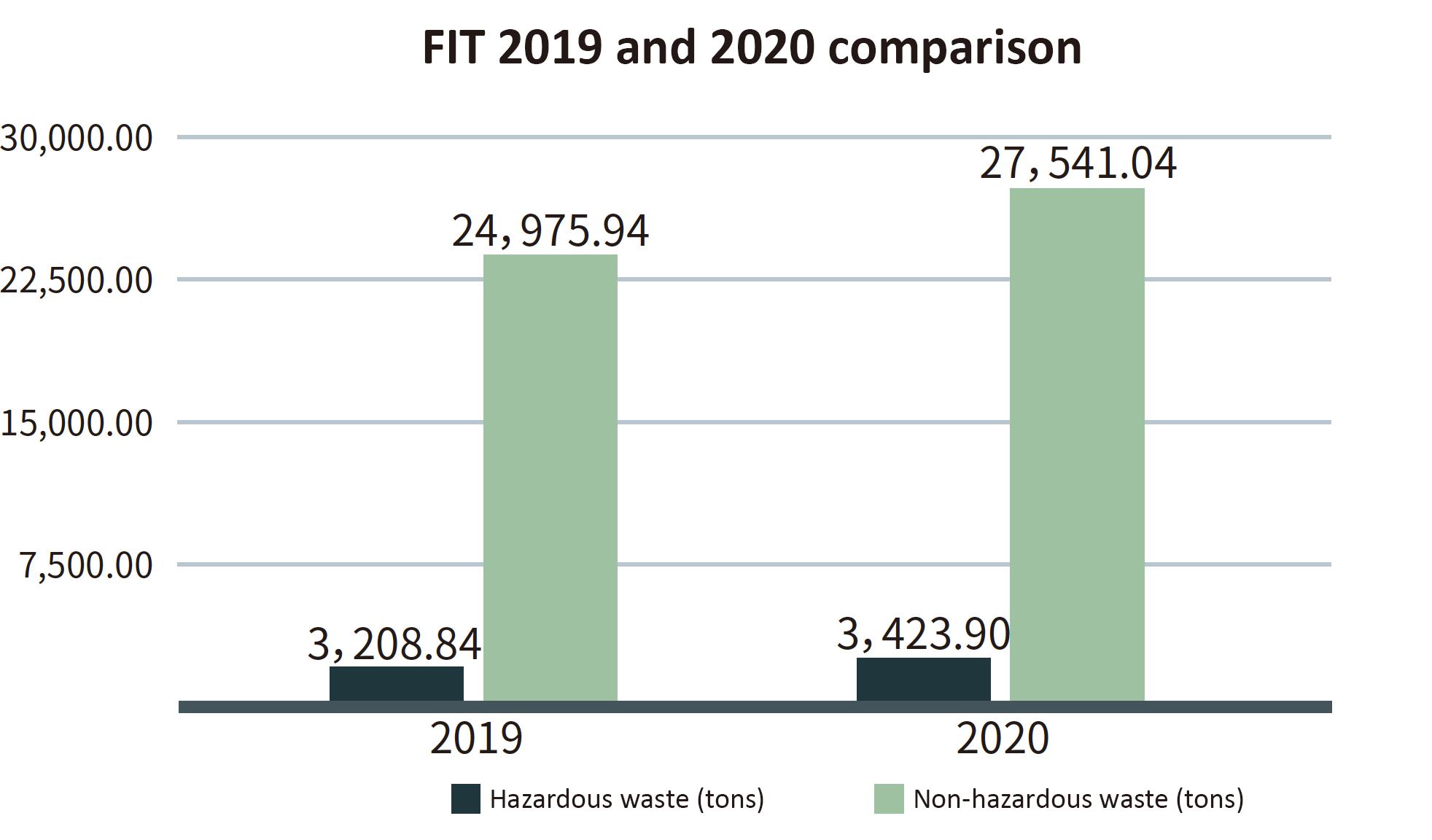

Waste management is an important part of FIT's prevention and control of environmental pollution, and the procedures for identification, collection and storage, and disposal of various types of waste are clearly regulated. Based on the existing waste disposal methods, FIT is also continuously optimizing the waste disposal methods, including reducing incineration, switching to more recycling methods, and avoiding environmental damage as much as possible in the production process. raw materials or processes. In 2020, the company will use the sludge to plant a total of 5,000 trees in the plant area to recycle waste and successfully reduce sludge emission by 10%. |  |

|

tabC class=title addgreencheck

|

|  Integrity enterprise Integrity enterpriseIn 2020, FIT Chongqing and Zhengzhou factories won the title of "Integrity Enterprise" in the corporate credit rating. |

|  Green factory Green factoryIn 2020, FIT Shenzhen factory won the title of "Green Factory" promulgated by the local government. | |

|

class=medallist

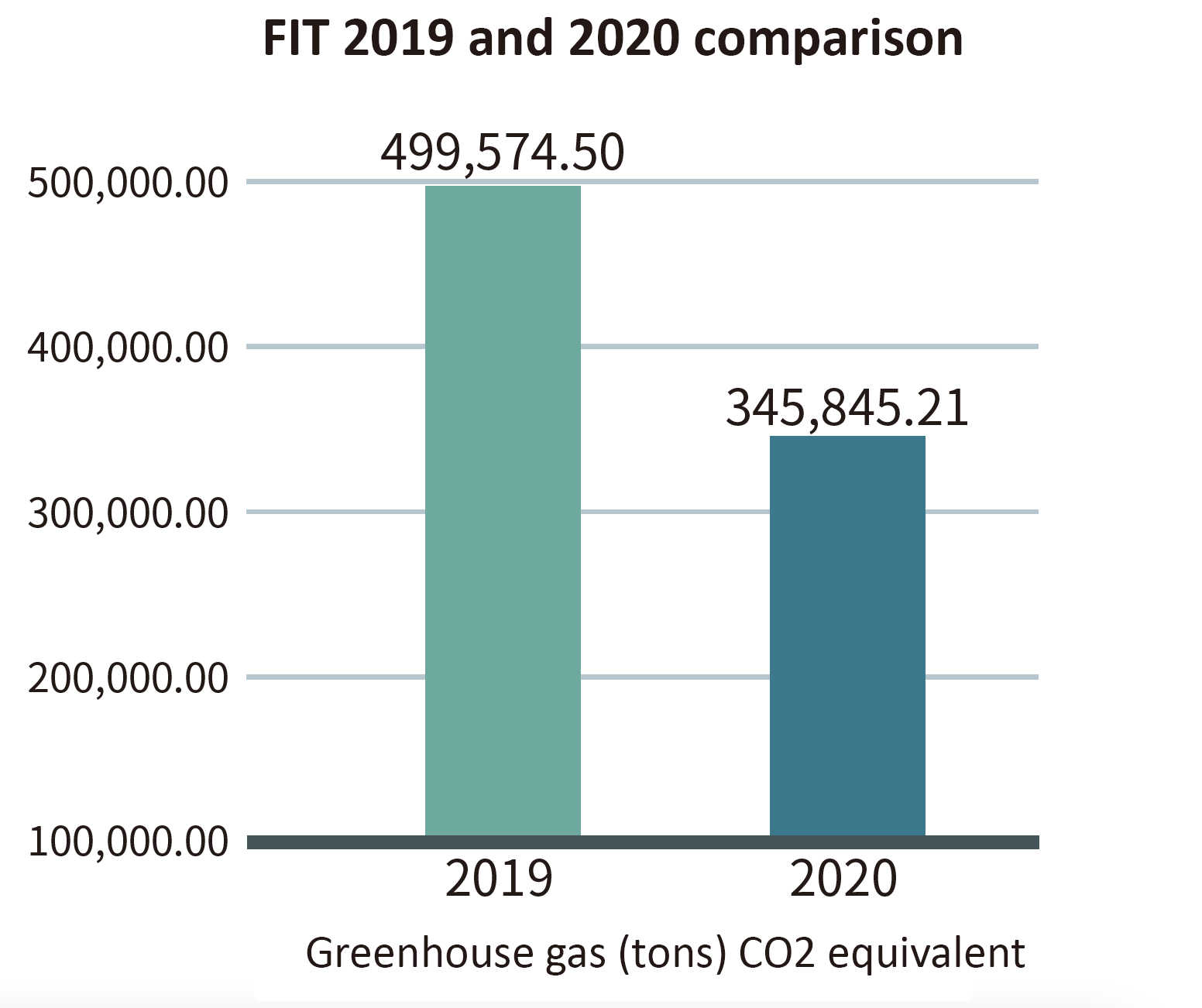

Greenhouse gas management |

class=title airmanipulate

Every year, the company sets emission reduction targets based on the actual situation and establishes corresponding emission reduction targets. , In 2020, the FIT mainland plant has set a goal of reducing carbon emissions per unit of output value by 6.25% year-on-year compared to 2019. |  |

|

class=airmanipulate addgreencheck

|

|

| |